* Note CC6566 is now CC6571 Tier4 Final

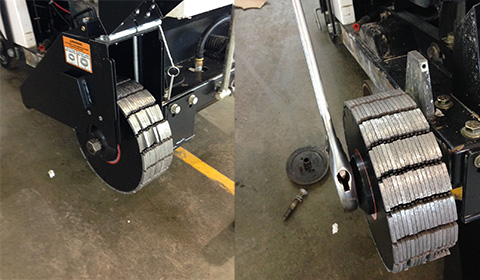

We’ve all hit an off-ramp going a little faster than you’re supposed to and been startled by the rumble strips. It really is the best way to alert drivers there is a change in the roadway ahead and you need to slow down. Have you ever wondered how those rumble strips get put there? Recently we had an opportunity to work with our friends at our regional DOT as well as Diamond Products who makes a nice converts kit for their most popular walk behind concrete saw Core Cut CC6571. The kit very easily turns the saw into a transverse rumble strip machine with a 4” width capacity.

The Core Cut CC6571D-36 large concrete saw from Diamond Products is a powerful, full sized self-propelled concrete saw that gives maximum large saw performance and output at the lowest price in its class. The very smooth running, liquid cooled, four cylinder Kubota diesel engine is very powerful yet has moderate fuel consumption, and can be used in a wide range of contractor and industrial applications. Easy to fit into a trailer with water tank and other necessary accessories. This unit definitely has the power needed for installing the 4” wide rumble strip.

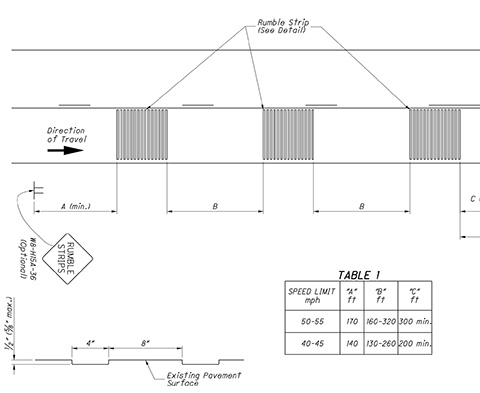

Transverse rumble strips, also referred to as bar markings, are placed across the traffic lane to make sure motorists are alerted to hazards ahead, such as areas of pedestrian activity, bends in the road or intersections. They are typically useful where drivers have been travelling continuously at high speeds for a long period of time.

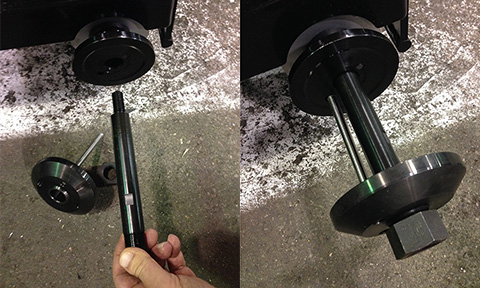

The 4” blade spacing kit (6010632A) can be added to the standard saw with very little additional work. The kit includes a wide guard to accommodate the four inch wide stack of blades and spacers. The (16) 12”x.250” blades and (15) spacers that go between each blade are added as shown below. Finally, the guard is installed. Now you are ready to install precision 4” transverse rumble strips.

The next step is to determine transverse rumble strip layout. Touch the diamond blade head to the roadway surface with the engine off and set the depth indicator to 0”. Now, start the engine and lower the diamond head down until the depth indicator reads the depth specified for your rumble strip. Set your depth stop on the saw so the head can go no deeper than the amount required for the rumble strip specification. Finally, begin your pass, making sure your travel speed is slow enough that the saw does not ride up and give you inconsistent depth.

The CC6571D-36 concrete saw has a transverse mounted Kubota diesel engine. It is rated at 66 horse power and its transverse mounting makes this saw the most maneuverable of other large saws. The engine is protected by an advanced cyclone air filter system for maximum engine life. The liquid cooled, four cylinder engine is a very smooth running power plant ever on such a large saw.

This saw includes a hydraulic raise and lower system for precise depth control and a dash mounted depth indicator for improved operator control. The saw features self-propelled operation with an Eaton transmission and two position handle bars for increased operator comfort.

The blade guard and blade can be mounted on either the right or left side for sawing in difficult to reach or tight areas. The saw is generally used with water, but may be used in dry applications with the correct type of blade. This Core Cut large saw has an oil bath blade shaft which means your operators won’t have to grease any grease fittings, leading to dramatically longer blade shaft bearing life. Finally, it has a belt tensioning system that is superior to any other large saw belt tensioning system, which means more power to your blades as well as longer belt life.

For any questions on walk behind concrete saws, the rumble strip kit or diamond blades in general contact the experts at Ohio Power Tool 800-242-4424. These guys have extensive training in cutting a wide variety of materials and applications.