This week, we’ve got a sneak peak at a new FLEX saw unlike anything you’ve seen before. Plus, Todd picks the best gloves and Robillard’s merry men pick the best jigsaw. THIS is your power tool week in review.

Tool Box Buzz | D-Handle Jigsaw

Today we have several tool stories for you, starting with the crew at Tool Box Buzz who decided to test every D handle jigsaw they could find.

This is a Tool Box Buzz Head 2 Head, which means a team of at least, oh I don’t know, let’s say 40 guys, take 15 different jigsaws, and build jigs that are just about more complex than the tools they’re testing. This time around they tested power, speed, accuracy, ergonomics, vibration, value and more. They included examples from every point on the spectrum including Festool, Milwaukee, Dewalt, and even Ryobi, Skil and Black and Decker. If you have a question…. ANY question at all, The TBB Crew has the answer. You can watch the entire event at Tool Box Buzz.

Project Farm | Best Work Gloves

Speaking of ridiculously detailed head 2 heads, Todd is back again this week. This time he’s testing work gloves, so of course, he put them all in a bear trap. Because he’s Project Farm.

As a guy with delicate man baby hands, I love work gloves. I do a lot of outdoor work on our property and I’m always on the lookout for a better set of gloves. As per usual, Todd designed several creative test setups to test durability, grip, puncture and cut resistance. And yeah, only Project Farm could make this so watchable. It has to be his pacing. His tests move like they were written by Aaron Sorkin. Anyways, We get to see brands like Milwaukee, Mechanix, Carhartt, VGO, Ironclad and more. So before you buy your next set of work gloves, head over to Project Farm

Shop Tool Reviews | Makita X-Lock

Just a few weeks ago Makita announced they were choosing to raise the X-Lock flag along side Bosch, and added the system to a new group of grinders. And Fortunately for us, Tim over at Shop tool Reviews got his hands on one.

THIS is the Makita XAG-26 18V Brushless Grinder, and it’s now easier than ever to swap out your grinding wheels, flat discs and carving tools, thanks to the adoption of the X-Lock system. We’ve featured X-Lock before on the show. It was developed by Bosch, who decided to make the design available to anyone who wants it… and of course, is willing to pay for it. Makita is just the latest of 39 other companies now building X-Lock Grinders or accessories, which is a good thing considering how good Makita’s grinders are. And this new XAG-26 is no exception. It features a brushless LXT Motor, paddle switch, which I prefer myself, and at only 6lbs with a battery, it’s ergonomic too. But it’s the new X-Lock compatibility that stands out, and fortunately, it doesn’t appear to raise the price much if at all. For the full review, head over to Shop tool Reviews

Tool Talk | FLEX

Ok it’s time for Tool Talk guys. Last week we asked you to let us know if Makita’s road map for their new XGT 40 and 80V line of tools made sense, and you all had a lot of strong opinions. MrJay06 said “I’m invested in Makita’s LXT line more than anything else but I won’t be moving to their 40v platform as I simply don’t NEED to. I want to though.” and immediately two other commenters agreed.

Albert Giaquinto, there’s no way I’m pronouncing that right, said “I think it’s a smart play from Makita to offer the different platforms instead of forcing their clients to change to a power level they might not need. I think they are going for a wider range of customers from home diy entry level to handyman and light duty installers to their new line up being geared toward heavy duty work sites without power.”

There were of course several anti-teal guys out there, but for the most part the majority of our fans seemed to like Makita’s plan, which surprised me. Now we just need to see if their LXT platform can survive the growing onslaught of cheap knockoffs that are becoming more prevalent every day.. But we’ll save that for a future tool talk.

Today, we’re going to talk about FLEX. Unless you haven’t been on social media for a week, you likely know that Lowes accidentally posted a FLEX multi-tool kit early on their website. For context, they haven’t officially revealed ANY of the new tools yet. But no worries, they can just cancel the order and OH NEVER MIND. They shipped them.

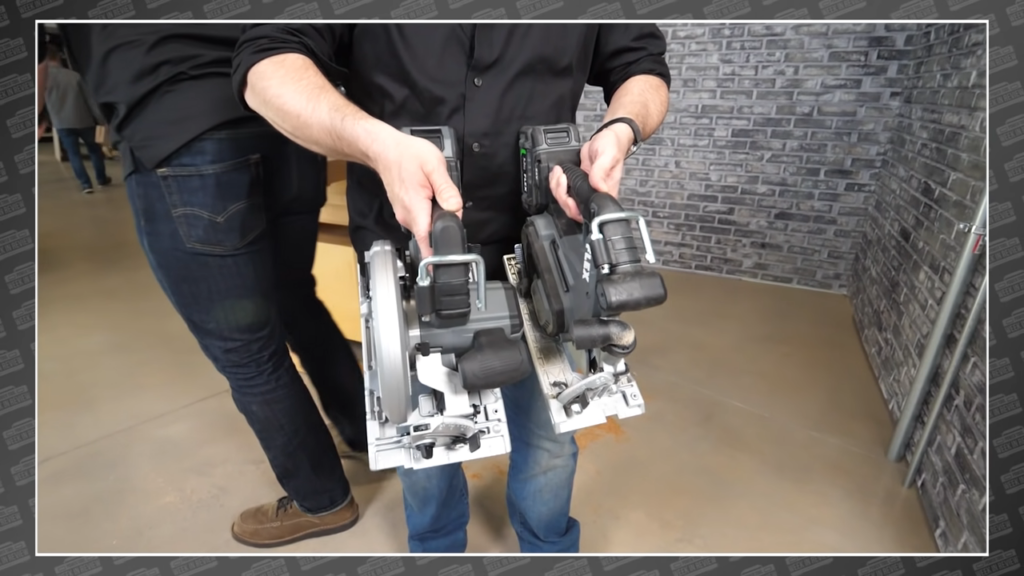

AS you can see behind me, we have them too. Like several other power tool content creators, we got them early, but we’re not allowed to show them to anyone or talk about them, until after the April 12th launch. That was until the Lowes screwup, at which point we were told we could show you the tools, but not reveal any stats, or run tests. So, there they are. But Sarah and I were not satisfied. Despite not leaving our compound for the last year, FLEX allowed us to make a special 1 day round trip to Chicago for a highly controlled, socially distanced peek at the full line. For a few hours we had the pleasure of running many of the same tests they’re going to show you in their launch video on the 12th. We also got our hands on each tool, and were allowed to try them all out. With all that said, I asked FLEX if we could show you the one tool that really had us in awe, and they said… yes.

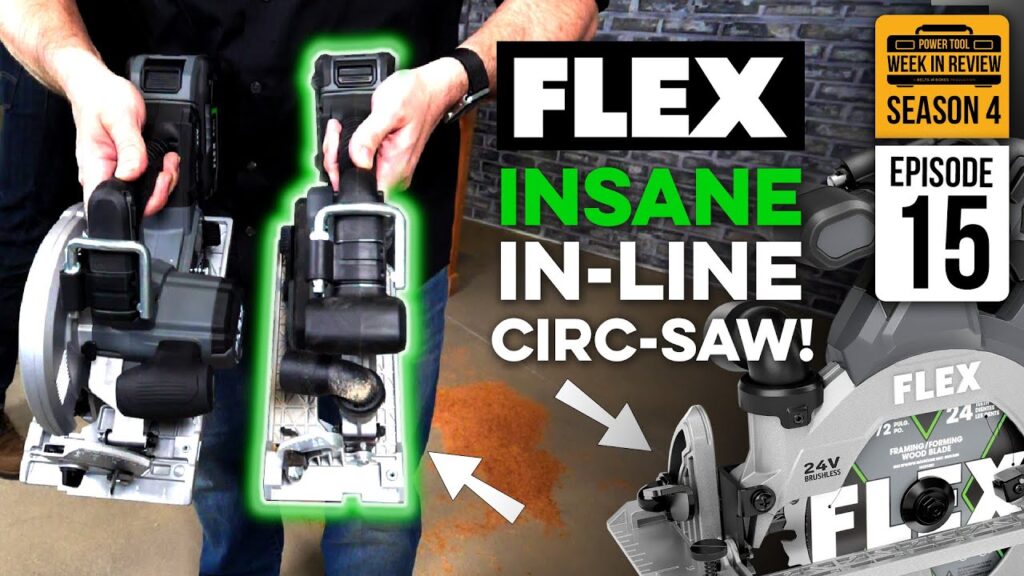

So, THIS is the all new FLEX In-Line Circular Saw it has a standard 6 ½” blade, but that’s where the normal stuff ends. AS you can see, this saw is not a right or left hand saw. The motor, handle and battery are all perfectly in line with the blade, making it easy to see from either side. Here it is next to their new 7 ½ standard circular saw. Look how skinny that thing is! I got to use it too, and it was “_______________________________________________” which we have to bleep because I can’t tell you that. I can’t tell you any of the stats, but since you can see it, I want you to look closely at something. They moved the motor behind the blade, and connected it with a belt drive. With the thickness of the motor no longer on the blade axis, you can now move the center of the blade closer to the plate, giving you crazy cutting depth with a 6 ½” blade. I accidentally held that square up to the board I was cutting through, so do look too close. What I can tell you? An M18 7 ¼” circular saw’s cutting depth is… yup. 2 ½” Interesting.

They told us this saw has been an internal passion project for well over a decade. But it took a new line of tools, aimed at the top of the class, and backed by a private company with leaders who are idealistic, visionary and dedicated not just to the performance of tools, but to the performance of the tradespeople, they’re building the tools for. This was just one of the amazing innovations they showed us, and every time we asked about the future, it seemed to boil down to this… if it comes in Red, they’re going to make a better one.

So this week, while we wait for the April 12th launch, I want to ask you guys this. If you had the insane resources they have at FLEX, and you were designing your own roadmap, where would you go next? After your initial line of power tools, do you go into specialty tools? HVAC, Plumbing, Framing? Or what about building a proper competitor to PACKOUT? I want to hear about it in the comments below, and I’ll look for you guys in the live stream on Monday.

Speaking of world domination, last week we took a look at Makita’s plan take your money, which you can watch right here.

Special thanks to Ohio Power Tool and EGO for sponsoring this episode!